Category

- Stranding Machine

- Double Twist Machine

- Single Twist Cabling Machine

- Core Wire Extruder Machine

- Sheath Cable Extruder Machine

- Wire Drawing Machine

- Twist Buncher Machine

- Double Twist Stranding Machine

- Foaming Extruder Machine

- Armoring Machine

- Copper Tape Shielding Machine

- Steel Tape Armoring Machine

- Take Up Machine

- Pay Off Machine

- Motorized Pay Off Machine

- Passive Pay Off Machine

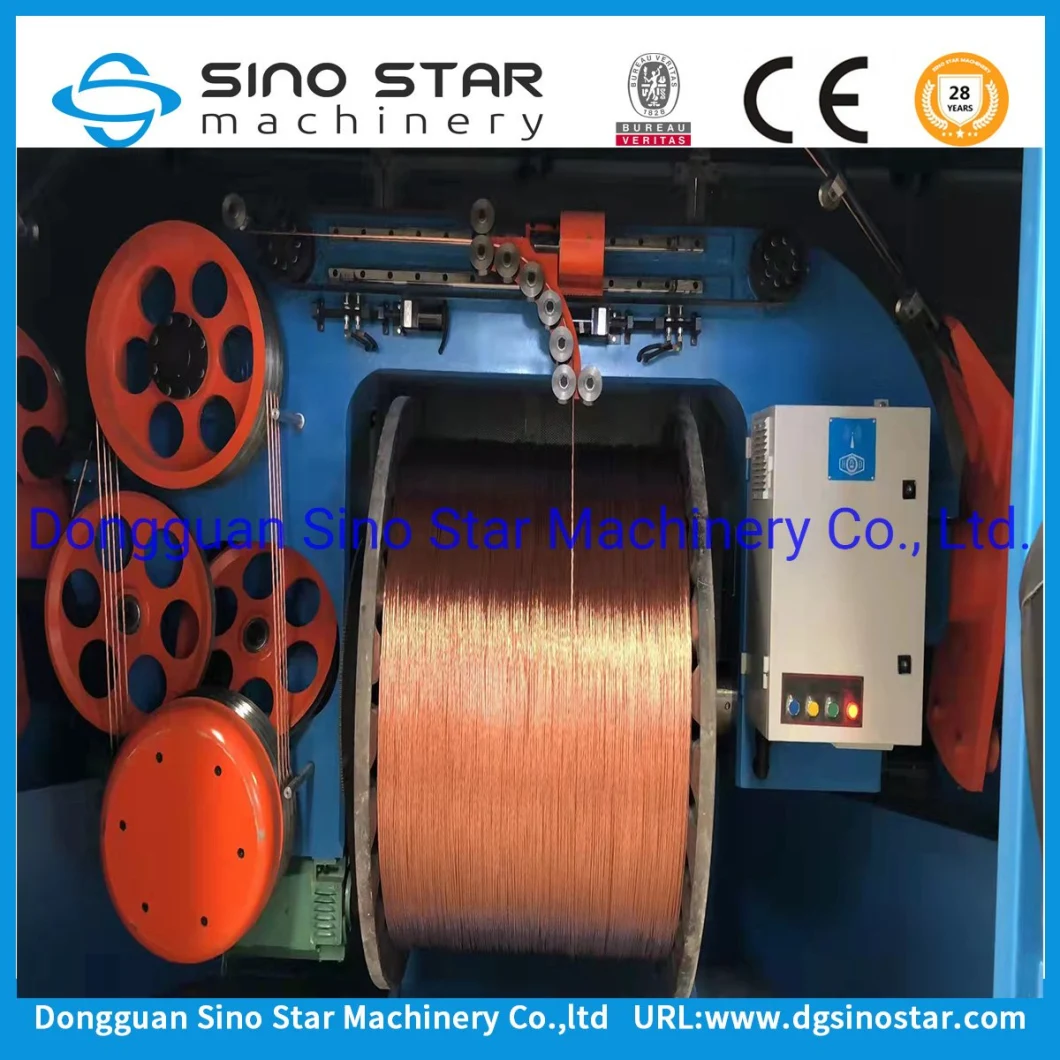

High Speed Twisting Bunching Stranding Winding Making Machine for Bare Copper and Aluminium Cables

High Speed Twisting Bunching Stranding Winding Making Machine for Bare Copper and Aluminium CablesNew type double twisti

Basic Info

| Model NO. | SS-EDT1600 |

| After-sales Service | Available |

| Driven Type | Electric |

| Condition | New |

| Certification | RoHS, ISO, CE |

| Warranty | 24 Months |

| Automatic Grade | Automatic |

| Mould Life | >1,000,000 Shots |

| Type | Double Stranding Machine |

| Motor Brand | Siemens |

| Inverter Brand | Siemens |

| PLC | Siemens |

| Touch Screen | Siemens |

| Low-Voltage Electrical Parts | Specified by Customer |

| Bearing | NSK |

| Painting | Customzied |

| Transport Package | Wooden Cases |

| Specification | L6200*W2500*H2800 |

| Trademark | SINO STAR |

| Origin | Dongguan, China. |

| HS Code | 8479400000 |

| Production Capacity | 260 Sets/Year |

Product Description

High Speed Twisting Bunching Stranding Winding Making Machine for Bare Copper and Aluminium CablesNew type double twisting machine for stranding copper wires and cables suitable to bobbins ranging from 1250mm to 1600mmSINO STAR New type high speed double twist bunching machine, double stranding machine, double twisting machine for stranding wire and cable suitable for bobbin from DM1250mm to DM1600mm

We have been producing NEW TYPE high speed double stranding/twisting machine, double twist bunching machine since 2008 and have exported many sets of this kind of machines to our overseas customers from Italy, Spain, Morroco, Romania, Slovakia, Chile, Ecuador, Bolivia, Brazil, Japan, Vietnam, Thailand, Russia, Uzbekistan and Iraq etc. We have been dedicated into making cable machine for over 3 decades; I am pretty sure that we can offer you the best solution for the cable production line with the most competitive price and excellent service.

We started to manufacture the first European double twist bunching machine suitable for the bobbin 1250mm and the bobbin 1600mm in 2008. We sold the first set of 1250mm double twist bunching machine to the European local cable manufacturer in 2008 for our Spanish customer. After that time we have been always improving and manufacturing this kind of double twist bunching machine.Application: this kind of new type double twist stranding machine is applicable to the twisting of coated cored wires such as rubber wires, data wires, electronic wires, power wires, control cables and multi-strand bare copper cables.Now we mainly have 2 models. One is for 1250mm bobbin and the other one is for 1600mm bobbin.Main technical parameters for the European double twist bunching machine are as follows:

| Model | SS-EDT 1250 | SS-EDT 1600 |

| Pitch range | 40mm-350mm or customzied | Internal setting tracking tension |

| Bobbin size | Φ1250mm | Φ1600mm |

| Applicable single wire diameter | Φ3mm-Φ8mm (cored wire)Φ1.7mm-Φ2.6mm (flexible copper)Φ2.0mm-Φ3.0mm (flexible aluminum wire) | Φ1.7mm-Φ2.6mm (flexible copper)Φ2.0mm-Φ3.0mm (flexible aluminum wire)Φ4mm-Φ6mm (multi-core cored wire) |

| Stranded outside diameter | Φ8mm (copper wires)Φ8mm (aluminum wires)Φ24mm (cored wires) | Φ10mm (copper wires)Φ9.5mm (aluminum wires)Φ24mm (cored wires) |

| Line speed | Max. 250m/m | Max.200 m/m |

| Driven force | 60HP | 75HP |

| Rotary speed | Max.750RPM | Max.400RPM |

| Stranding direction | Either left twisting direction or right twisting direction | |

2. Main characteristics:

* High output: high rotary speed, the speed of this double twisting machine is the most highest among the same models made in China and its production efficiency is twice of the traditional twisting machine.

* Robust: The mainframe base and frame are reinforced and the carbon fiber stranded bow is imported originally, which improves the steability of running dramatically.

*Stable tension: Take-up tension keep constant from empty bobbin to full bobbin.

*Precise pitch: PLC control+ frequency conversion adjustment. All parameters of the complete machine can be set and stored on the touch screeen. The pitch is very stable and its error is less than 3% in the course of accelerating and decelerating.

* Neat traversing: take-up traversing postion adopts axial traversing type. Traversed scope and traversed distance can be set arbitrarily on the touch screen.

*High quality: less blending, product electrical performance won't be destroyed.

The photos of NEW TYPE high speed double twisting machine are listed out below for your reference.

Our Service Pre-sales service including:- Analyse customer's inquiry and reply to customer within 12 hours after receiving the inquiry from customer.- Communicate with customer and help customer to choose the well-suitable machines for customer.- Sending drawings to customer for confirmation to make all is clear before placing order with us.- Prepare the final proposal for customers- Invite customer to visit our factory or we can visit our customer's factory to held a face-to-face meeting if possibleAfter-Sales Service- Training customer's workers how to install, operate and maintain our machines - Engineers available to provide overseas maintenance service for all our machines working abroad.Customers Q&A: A1: Are you the manufacturer or trading company ?Q1: We are the factory with 3 big workshops covering 6000 s.q.m; Warmly welcome you to visit our factory and conduct our work.A2: What's your factory's advantage over other manufacturers in the same industry ?Q2 - High output capacity will guarantee your high-efficient production - We are very good at engineering; In order to make our machine have a very excellent performance; we are rigorously attaching importance to each detail in the course of manufacturing in a bid to improve our machines continuously. - We only mount electrical components under famous brands like Siemens,Yaskawa, Scheinderand Omron on our machines to guarantee the quality of our machines. - Our engineers and workers can work abroad; if you need us to assist you installing and testingthe machines or training your staff how to operate and maintain our machines; we can send our team to your factory when our machines arrive at your factory. - Guarantee period: We can guarantee two years for all our machines - After-sales service: We promise to provide permanent technical support and after-sales service with our customers.A3: Why do we trust your company ?Q3: We have been engaging into cable machinery industry for over 30 years and have agent in Europe since 2007. Up to now we have exported our machines to many countries.A4: Where is your factory ? How can we visit you ?Q4: Our factory is located in Dongguan, Guangdong Province, China, very close to Shenzhen and Guangzhou. You can pick you up at Humen railway station (you can take high-speed train from Guangzhou South Railway sation or Shenzhen North station, it takes you only 10 minutes by high speed train to reach Humen Railway station)

We are sincere to long for working together with customers from all around the world. Warmly invite you visit our fatory DONGGUAN SINO STAR MACHINERY CO.,LTD at your convenient time !