- Stranding Machine

- Double Twist Machine

- Single Twist Cabling Machine

- Core Wire Extruder Machine

- Sheath Cable Extruder Machine

- Wire Drawing Machine

- Twist Buncher Machine

- Double Twist Stranding Machine

- Foaming Extruder Machine

- Armoring Machine

- Copper Tape Shielding Machine

- Steel Tape Armoring Machine

- Take Up Machine

- Pay Off Machine

- Motorized Pay Off Machine

- Passive Pay Off Machine

Wire and Cable Making Machine Manufacturers & Suppliers with 1+6+12+18 Copper Wire, Aluminum Wire Stranding Machine

Basic Info

| Model NO. | HH-500/630 |

| Mould Life | >1,000,000 Shots |

| Type | High-speed Stranding Machine |

| Usage | Stranding |

| Technical Support | Overseas Support |

| Speed | 70 M/Min |

| Conductor Size | 1.5 mm-5.0 mm |

| Conductor | Copper Wire,Aluminum Wire |

| Color | Customized |

| Model | Hh-500/630 |

| Style | High Function |

| Exported Experience | Over 15 Years |

| Motor | Siemens |

| Transport Package | Plastic or Wooden |

| Specification | 500/630 |

| Trademark | HOOHA |

| Origin | Guangdong |

| Production Capacity | 5 Sets/Month |

Product Description

1+6+12+18 Copper wire,aluminum wire stranding machine

Product Description

It is used for the wring and compacting of fan-shaped conductor, wringing and drawing of circular conductor, and pre-wringing and wringing of conductor core. Mainly used for copper and aluminum conductor cables twisted wire system fan pressed,pressed and drawn round conductor segment conductor strands twisted pre-pressed

Charateristic

Advantages :1. High speed: the maximum speed of 630 wire disc 6 discs reaches 350rpm;

2. Multiple specifications: the minimum diameter of wire disc should be 400mm and the maximum diameter should be 800mm. The minimum number of single segment wire disc should be 6 and the maximum number should be 48.

3. Multi-form tension: hysteresis tension, mechanical tension, mechanical belt feedback tension, pneumatic tension, etc.

4. hydraulic, electric side lower upper plate, side upper plate and so on a variety of overall plate options;

5. manual clamping, pneumatic clamping, electric clamping and other clamping mechanisms can be selected.

Trait:

1. Design the top hole of special machine processing frame to ensure the concentric degree of two holes so as to avoid the concentric problem affecting the tension;

2. Optimized clamping structure, more stable pneumatic tension, more reliable clamping bearing;

3, ground shaft type frame stranding gear box gear tooth grinding processing to reduce noise;

4. The design and optimization of the installation mechanism of the drive shaft of the frame stringing synchronous belt of the motor division ensures the machining accuracy and facilitates the tensioning adjustment of the synchronous belt;

5. Newly added upper disc mechanism at the lower hydraulic side enriches the upper disc varieties;

6. The newly added electric clamping mechanism enriches the clamping form.

Product Parameters

| Item | Unit | F-JLK500 | |

| Stranding-single wire Dia. | mm | Copper | Ø1.5~4.5 |

| Aluminum | Ø1.8~5.0 | ||

| Max. section area | mm2 | Copper | 500 |

| Aluminum | 630 | ||

| Cage rotating speed | r/min | 63~148 | |

| Hauling line speed | m/min | 6.87 ~ 52.2 | |

| Stranding pitch | mm | 47 ~ 825 | |

| Capstan Dia. | mm | Ø 2000*2 | |

| Central payoff bobbin size | mm | PN1600 | |

| Payoff bobbin size in cage | mm | PND500 | |

| Takeup bobbin size | mm | PN 2500 | |

| Machine center height | mm | 1000 | |

| Main motor power | KW | 55 | |

| Item | Unit | F-JLK630 | |

| Stranding-single wire Dia. | mm | Copper | Ø 1.5~4.5 |

| Aluminum | Ø 1.8~5.0 | ||

| Max. section area | mm2 | Copper | 300 |

| Aluminum | 400 | ||

| Cage rotating speed | r/min | 6 Bobbins | 75~174 |

| 12 Bobbins | 67~156 | ||

| 18 Bobbins | 57~133 | ||

| 24 Bobbins | 48~112 | ||

| 30 Bobbins | 43~100 | ||

| Hauling line speed | m/min | 6~45.6 | |

| Stranding pitch | mm | 34~1041 | |

| Capstan Dia. | mm | Ø 2500*2 | |

| Central payoff bobbin size | mm | PN1600 | |

| Payoff bobbin size in cage | mm | PND630 | |

| Takeup bobbin size | mm | PN2000 | |

| Machine center height | mm | 1000 | |

| Main motor power | KW | 45 | |

What do we focus on

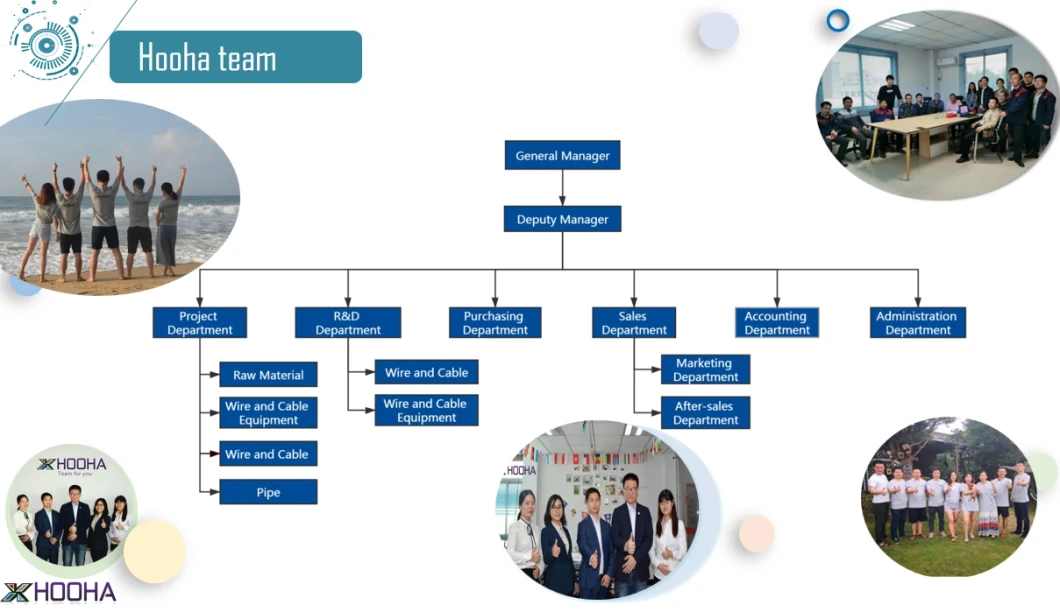

HOOHA team always here for you!

We provides a series of solutions in wire and cable field to help promote improvement of our customers' business. we not onlyprovide equipment and solutions, but also focus on offering high-quality service such as free layout design of cable factory, overseas installation guidance, operation training and so on.Upgrating service:

1. Design the top hole of special machine processing frame to ensure the concentric degree of two holes so as to avoid the concentric problem affecting the tension;

2. Optimized clamping structure, more stable pneumatic tension, more reliable clamping bearing;

3. Ground shaft type frame stranding gear box gear tooth grinding processing to reduce noise;

4. The design and optimization of the installation mechanism of the drive shaft of the frame stringing synchronous belt of the motor division ensures the machining accuracy and facilitates the tensioning adjustment of the synchronous belt;

5. Newly added upper disc mechanism at the lower hydraulic side enriches the upper disc varieties;

6. The newly added electric clamping mechanism enriches the clamping form.

Detaied photos:

Successful Cases

We are a Hong kong company, focusing on in-depth cooperation with Chinese leading wire&cable equipment companies and wire&cable manufacturers to provide advanced wire&cable production solutions and service.

Now we are continuously updating our solutions in the field of wire and cable, making great effort to keep improving our design level and R & D strength to provide customers with more superior wire and cable solutions.Market:

We have provided professional wire and cable solution for more than 100 customers around the world. The main markets are as follow1.Southeast Asia(eg:Indonesian customer Pt sinarmonas industries)2.South Asia(eg:Indian customer ESSEM Srinisons Systems Pvt Ltd.)3.East Asia(eg:Japanese customer KDK Electric wire.)4.North America(eg:American customer General technologies, Inc.)5.South America (eg:Brazilian customer Fibracem Teleinformatica Ltda)6.Eastern Europe(eg:Ukrainian customer Deep Networks Group)7.Africa(eg:Angola customer W-VOA-fabrica de cabos de angola,lda.)8.The Middle East(eg:Dubai customers Power Plus Cable Co., L.L.C.), etc.

Customer Evaluation

Address:Located in Humen Town,Dongguan City,Guangdong province,China.Add: 3 rd Floor, Building D, No.38 Houhu Road, Humen Town, Dongguan City, Guangdong Province,ChinaHongkong airport to Humen by boat 2 hoursGuangzhou airport to Humen by car 2 hoursShenzhen airport to Humen by car 1 hourGuangzhou South high speed train station to Humen 20 minutesShenzhen North high speed train station to Humen 20 minutes