- Stranding Machine

- Double Twist Machine

- Single Twist Cabling Machine

- Core Wire Extruder Machine

- Sheath Cable Extruder Machine

- Wire Drawing Machine

- Twist Buncher Machine

- Double Twist Stranding Machine

- Foaming Extruder Machine

- Armoring Machine

- Copper Tape Shielding Machine

- Steel Tape Armoring Machine

- Take Up Machine

- Pay Off Machine

- Motorized Pay Off Machine

- Passive Pay Off Machine

Automatic PP/PE/PVC/HDPE Insulating Sheath Cable Extruder Extrusion Machine Line for Wire Power Cable Umbilical

Basic Info

| Model NO. | Alpha |

| Material | PVC,PE,HDPE,MDPE,TPU |

| Screw L/D Ratio | 25:1 |

| Screw Diameter | 45-150mm |

| Traction Method | Automatic Industrial Rubber and Power Cable Extrud |

| Power Supply | Three Phase, 240/480V/510 60Hz with Neutral Wire |

| Extrution Output | PE, 600kg Per Hour TPU,20rpm |

| Before The Sheath Core Diameter | Dn40-190 |

| After The Cable Insulation Diameter | Dn50-200 |

| Length of The Water Tank, | Single Layer, 4+20meters |

| Center Height | 1000mm |

| Production Name | Popular Building Cable Insulation Sheath Productio |

| Temperature | 0 to 46 |

| Humidity | 0-95% Rh |

| Speed of Screw | 68rpm |

| Max. Extrusion Output | 600kg/H, for MDPE |

| Transport Package | Wooden Tray |

| Specification | 20000*2500*2200mm |

| Trademark | HLT |

| Origin | China, Jiangsu |

| HS Code | 8477900000 |

| Production Capacity | 5000set/Year |

Product Description

Automatic PP/PE/PVC/HDPE Insulating Sheath cable extruder Extrusion Machine for WIRE Power Cable Umbilical

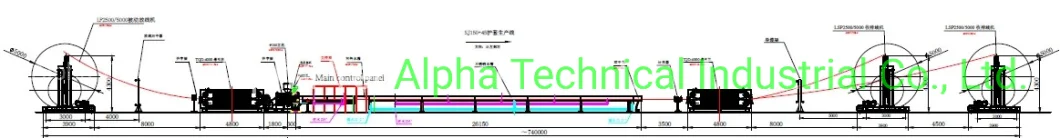

Raw material (PP,PE,PA,PET)--------Pay-off --------Caterpillar------ Extruder head------Water cooling------Drying--------Caterpillar ------winder/take -up machine

Popular Building Cable Insulation Sheath Production Line is suitable for medium and high voltage single core or multiple core power cable sheath of extruded and double layer extruded at a time. Suitable material for PVC,PE,low smoke zero halogen,conductive PVC,and conductive PE and so on.

This equipment line can be used for loose tube puching oil gysts cable in the production of inner and outer sheath, at the same time it also can be used for parallel twin wire center tube cable totally medium messager aerial cable extruction production line.

| Popular Building Cable Insulation Sheath Production Line | |||

| Wire Core Diameter | DN3-30mm | ||

| Out Diamter | DN5-35 | ||

| Production speed | max 60m/min | ||

| Screw350KG/H | 350KG,/H | ||

| Z4dc Motor ,90kw | 1500 rpm | ||

| No. of Spinning Yarn Cluster | 2*24 | ||

| Relase Tension of spinning yarn cluster | 3-30N+-1 | ||

| Screw diameter | Φ150mm |

| Screw length to diameter ratio | 25:1 |

| Extrution output | PE:600kg/h ;TPU: 20rpm |

| Before the sheath core diameter: | Φ40-Φ90mm ; Φ90-Φ190mm |

| After the cable insulation diameter | Φ50-Φ100mm; Φ100-Φ200mm |

| The production line speed: | 20M/min(Max) |

| Traction method | Pneumatic flat belt |

| The length of the water tank, | single layer, 4+20meters |

| Pay-off reel | / |

| Take-up reel | / |

| Center height | 1000mm |

| Power supply | three phase,480V 60Hz with neutral wire |

Production Line Equipment Application :1,the cable machinery is Suitable for optical cable outer sheath and core strengthening comprehensive production, can also be used for inner protection layer production2,PE inner sheath,aluminum-plastic compound belt and PE inner sheath.3,PE outer sheath,aluminum-plastic compound belt,PE composite outer sheath,steel- plastic compound belt,PE composite outer sheath.4,Parallel double steel wire tube bundling type optic-fibet cable.Main Features:1) Compllete and reasonable equiments configuration. The main part adopt from internatonal famous brands, good appearance and easy operatopn.2) Multi-fuction. With single column double hanging motorized, it is more stable and reliable promance,Especially the DN800 double wire tension controller, it effectively protect core pay-off tension in the progress of instability.3) Easy operation with LPC system. the machine use PLC programmable controller. the main parameters all will show on screen, at the same time, it has alarm and power off memory fuction.4) 2*24 aramid twister can use for ADSS optical cables.

Finished Production:

Installation service

Production Package:

Professional ply wooden or iron pakage, or other Standard packaging for shipping sea shipping

About Alpha Factory:

Alpha Technical Industrial is a collection of scientific research and development and production of wire and cable equipment and a variety of efficient energy-saving extrusion production line of key enterprises, so far, the main product including wire and cable Insulation and Sheathing production Line, TQD series Pneumatic Type belt Caterpillar, LF series Portal Type Pay-off, LSP series Portal Type Take-up, Various Wire Accumulator, Capstan Haul-off, Pay-off & Take-up, Cooling Water Trough, and Optical Fiber Equipment, Communication Cable Equipment, Signal Cable Equipment.Our company has a technical administration team who engages wire and cable equipment industrial more than twenty years, as well as experienced engineer and skilled workers, our honest business reputation and good sales achievement, win the trust from our domestic and overseas customers, the products are exported to United States, France, Spain, Portugal, New Zealand, Brazil, Mexico, Chile, South Africa, Zambia, Egypt, South Korea, Singapore, Indonesia, Thailand, Iran, etc.

Clients Visiting and Instillation Service:

FAQ

− Q: Are you the manufacturer or trading company?

A: We are the manufacturer. We have a group of highly qualified engineers and experts, who have been working in the field of OFC equipment for more than ten years.

− Q: What is your company's main production?

A: We specialized in optical fiber and optical cable machine researching and manufacturing. Our products include Optical fiber coloring and rewinding machine series, Optical fiber secondary coating line series, Optical cable stranding line, Optical fiber cable sheathing line series and other optical cable equipment.

− Q: What can we offer our customers?

A: Our professional production and technical personnel can train our customers' employees and ensure the smooth production of customers. And will provide our customers with after-sales service.

− Q: How long is the machine warranty?

A: Warranty period of one year (since the completion of mechanical debugging at the buyer's factory)

− Q: Why do I choose your company? A: We have more than 10 years of professional experience in the production of cable machinery, providing high-quality, high-security products.

We have an experienced team of skilled workers and engineers.

We can support overseas training engineers.

We can customize the design, to accept the customer's sample design.

We can provide customers with after-sales service.

Enable us send you accurate machine offer. pls kindly send us the following information:

1. How many kgs/meters to extrusion per hour?2. Reel/Flange Diameter, we need to quote correct take-up and pay off machine3.Could you please send us your cable structure?4. Extrusion material of cable sheath and Cable sheath thickness5.Cable size 6.Cable pulling speed