- Stranding Machine

- Double Twist Machine

- Single Twist Cabling Machine

- Core Wire Extruder Machine

- Sheath Cable Extruder Machine

- Wire Drawing Machine

- Twist Buncher Machine

- Double Twist Stranding Machine

- Foaming Extruder Machine

- Armoring Machine

- Copper Tape Shielding Machine

- Steel Tape Armoring Machine

- Take Up Machine

- Pay Off Machine

- Motorized Pay Off Machine

- Passive Pay Off Machine

Jwell Plastic Extruder Price WPC Foaming PE Table/Beach Chair/Bench/Box/Garbage Can Plastic Machine

Basic Info

| Model NO. | JWS65/33; JWS75/33; JWS90/33 |

| Screw | Single-Screw |

| Automation | Automatic |

| Computerized | Computerized |

| Certification | CE, ISO9001:2008, SGS TUV UL |

| Customized | Customized |

| Motor Brand | China Top Brand |

| Usage | Used for Furniture |

| Material | HDPE |

| Advances | Sustainable |

| Machine Type | Profile |

| Profile | 120kg/H |

| Transport Package | Wooden Cases |

| Trademark | Jwell |

| Origin | China |

| Production Capacity | 700 Pieces Per Year |

Packaging & Delivery

Package size per unit product 2500.00cm * 250.00cm * 300.00cm Gross weight per unit product 10000.000kgProduct Description

Product

The HDPE foam production line newly developed by our company is widely used producing outdoor furniture, such as outdoor tables and chairs, beach chairs,park benches, flower boxes, garbage cans and garden fences.DescriptionsThe features:more environmental friendly than traditional materials, light density, low production cost, strong plasticity, good toughness, excellent weather resistance, long service life, colorful, good corrosion-resistant, easy to clean, nail holding force is better than WPC products, etc. The products are deeply loved by the people in developed countries.

Specifications

| Model | JWS65/33 | JWS75/33 | JWS90/33 |

| Product width | 240mm | 240mm | 400mm |

| Capacity | 30-50kg/h | 50-70kg/h | 80-120kg/h |

| Main motor power | 37kw | 45kw | 55kw |

Process Steps

Our Advantages

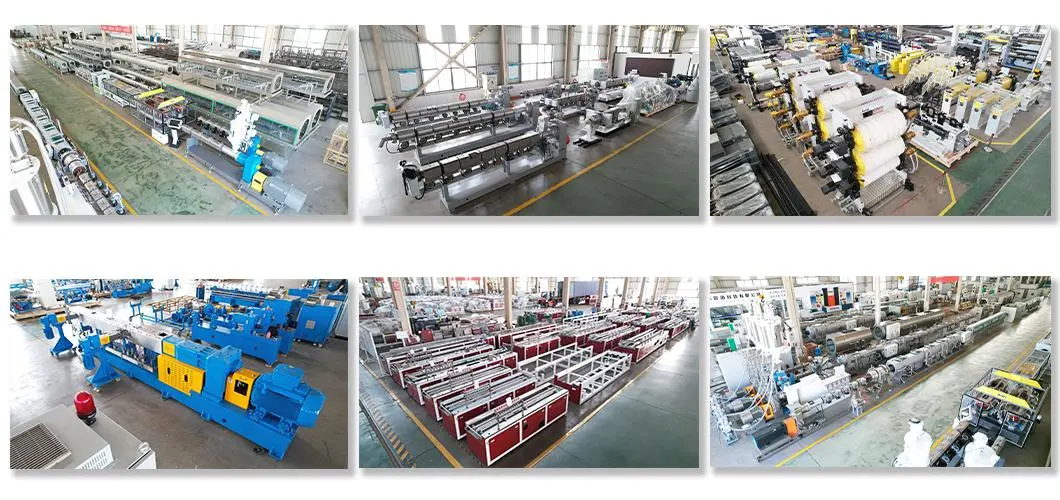

Workshop Processing

Packaging & Shipping

Certifications

Exhibitions

FAQ

Q1. What about the payment way?A1. By TT, L/C at sight or Alibaba trade assurance. 30% down payment should be paid after contract is valid, 70% balance should be paid before shipment.Q2. Installation and stuff training available from you?A2. Yes, we have rich engineers around the world which can send to your factory and train your workers. Also we can online guide your members.Q3. How long is the guarantee?A3. We offer you high quality machines with 12 months guarantee and reply you as soon as possible within 6 hours.Q4. If the machine some parts is broken one day, how can we get help from you?A4. We will send you spare parts free of charge If they are in warranty, not including easy-broken parts. For easy-broken parts, we will only charge a cost fee.Q5.How does your factory do regarding quality control?A5.We have passed the IS09001:2000 Quality Management System and CE certificate and we have a special QC department in charge of products' quality. If you also need other certificates, we also can help to apply.Q6. What is your packaging?A6. Our conventional packaging is: After doing the anti-rust treatment, wrap the plastic film around the machine and then fix the machine on the wooden bracket.Q7. How can we check the machines before delivery?A7. We can provide online checking when testing the machine on site. We will take and prepare detailed testing videos for your checking before the delivery. We accept third-party testing. Except above points,we will provide detailed testing report.