Category

- Stranding Machine

- Double Twist Machine

- Single Twist Cabling Machine

- Core Wire Extruder Machine

- Sheath Cable Extruder Machine

- Wire Drawing Machine

- Twist Buncher Machine

- Double Twist Stranding Machine

- Foaming Extruder Machine

- Armoring Machine

- Copper Tape Shielding Machine

- Steel Tape Armoring Machine

- Take Up Machine

- Pay Off Machine

- Motorized Pay Off Machine

- Passive Pay Off Machine

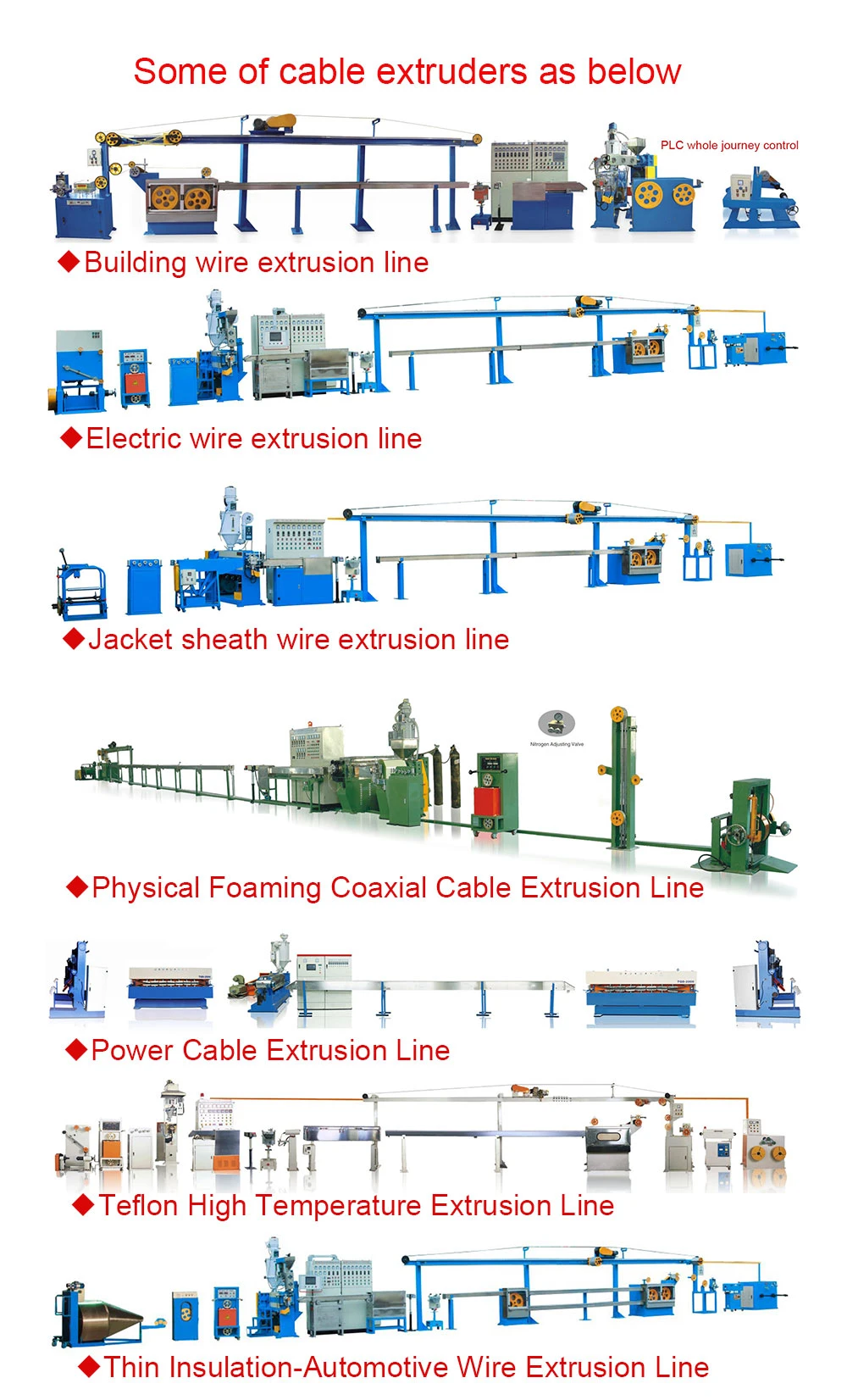

High Speed and Specical Design Communication Jacket Sheath Extruder Cable Machine

Jacket sheath extrusion cable machine Application Applied to BV,BVV,BVR,RV,Nylon sheath,and halogen-free environment-fri

Basic Info

| Model NO. | HH-70++90 |

| Cable Machine Speed | 460m/Min |

| Motor | Siemens |

| Bearing | Japan-NSK |

| Cable Machine Inverter | Yaskava |

| Electric Element | Siemens and Omron |

| Screw Material | 38crmoala with Nitrided Surface |

| Extrusion Capacity | 110kg / Hour |

| Cable Machine Button | Tiande |

| Cable Machine Bearing | NSK |

| Transport Package | Plastic Package |

| Specification | CE ISO SGS |

| Trademark | HOOHA |

| Origin | Dongguan, China |

| HS Code | 8479400000 |

| Production Capacity | 5 Sets/Month |

Product Description

Jacket sheath extrusion cable machine

Application

Applied to BV,BVV,BVR,RV,Nylon sheath,and halogen-free environment-friendly building wire.

Specifications

| Machine model | HH-70 | HH-80 | HH-90 | |

| Pay-off line type | Double axes/dynamic drum take-up | Double axis way | ||

| Pay-off bobbin size(mm) | 400-630 | 630-800 | ||

| Screw diameter(mm) | φ70 | φ80 | φ90 | |

| L/D of screw | 25:1 BM type | |||

| Extrusion capacity(kg/hr) | 140 | 200 | 250 | |

| Main unit power(HP) | 30 | 40 | 50 | |

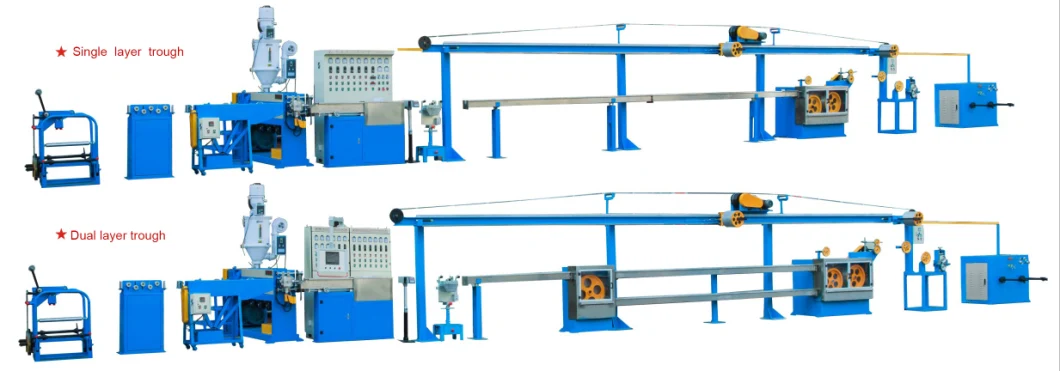

| Cooling device | Single layer/double | |||

| Accumulator capacity | 200m | |||

| Capstan power(HP) | 5 | 7.5 | 7.5 | |

| Wire speed(meter/minute) | 0-500 | 0-450 | 0-400 | |

| Take-up line type | Double axes bundle packing /axis packing/swaying tray coiler packing | Double axis way/axis | ||

| Receving reel | 500mm-630mm | |||

| Take-up line power(HP) | 5 | 5 | 7 | |

Spare Parts Brands

Motor: Dongguan Motor , Teco, ABB, Siemens

Inverter : Japan Yaskawa, Siemens, Taiwan Teco

Temperature Control Meter: Japan RKC;

Auxiliary Relay: Japan Omron ;

Ammeter and Voltmeter: Taiwan Risesun ;

Indicator, Switch and Button: Taiwan TEND ;

Contactor: Taiwan Shihlin

Line Speed Meter: Taiwan FOTEK/Yangming

Bearing : NSK, SKF

Delivery

Consisting Components

1,double-shaft pay-off rack

2,straightener platform

3,main extruder

4,automatic dryer and hopper

5,electric apparatus main control cabinet

6,Double layer movable trough

7,laser diameter gauge or Digital Diameter controller

8,high speed printing machine

9,double-wheels capstan

10,Meter counter

11,horizontal type wire-accumulator

12,power frequency sparker

13,double-shaft take-up machine

After service

1).Delivery dates: 45 days

2).Payment: TT or L/C

3).Packing: Wood packing and PE plastic packing ensure the goods safety on the transportation.

4).Install and training service: 2 professional engineers who has over 5 years overseas install and cable manufacture training experience.

5).After service phone number online

If the machine is not suitable for your wire spec., please contact me.

Contact us

Our Website: hoohaco.en.made-in-china.com

Add: No. 38, Houhu Road, Humen Town, Dongguan City, Guangdong Province, China

Location

Hongkong airport to Humen by boat 2 hours

Guangzhou airport to Humen by car 2 hours

Shenzhen airport to Humen by car 1 hour

Guangzhou South high speed train station to Humen 20 minutes

Shenzhen North high speed train station to Humen 20 minutes

Why us?

- We are the cable equipment manufacturer

- Professional engineer,long term to research and development for to cable equipment .

- High frequency capacity manufacturer machine is provide .Guarantee the machine all weather running .

- Our machine use the international qualified brand,like Siemens ,Omron,NSK,LG etc.

- Install and training service.Guarantee overseas install and cable manufacture training experience.

- Technical support and spare parts service.

Professional and Strong Manufacture and Sales Team

| Team of HOOHA service | |||||

| Name | education | Position | Mainly responsible for project | Specializing in project | Industry working history ( year ) |

| zanyang Xie | college | General Engineer | The total project design and planning | power cable machine | 15 |

| xioahua Hu | college | Vis general engineer | The total project design and planning | net cable,data cable machine | 10 |

| Chnaghong Cheng | college | Engineer | Drawings and after-sales service | Teflon,Optical fiber cable machine | 25 |

| xiuwu Chen | college | General Engineer | The total project design and planning | copper drawing machine | 15 |

| lixin Yuan | college | Engineer | The project design and planning | coppwer wire making technical | 16 |

| zhenghai Qiu | college | cable engineer | After service | cable making and cable factory management servie | 15 |

| jinxin Liu | college | Marketing engineer | After service | electrical engineer | 7 |

| xingguo Tang | High school | Electrical engineer | After service | electrical engineer | 10 |

| changqiang Li | High school | Maintain engineer | After service | machina maintain and install service | 10 |

| haipin Li | University | Engineering director | Marketing and sales | project consulting | 8 |

| sen Yang | University | Engineering translator | Marketing and sales | project consulting | 5 |