Category

- Stranding Machine

- Double Twist Machine

- Single Twist Cabling Machine

- Core Wire Extruder Machine

- Sheath Cable Extruder Machine

- Wire Drawing Machine

- Twist Buncher Machine

- Double Twist Stranding Machine

- Foaming Extruder Machine

- Armoring Machine

- Copper Tape Shielding Machine

- Steel Tape Armoring Machine

- Take Up Machine

- Pay Off Machine

- Motorized Pay Off Machine

- Passive Pay Off Machine

High Speed Metal Fabric Endless Take up Shuttle Wire Mesh Weaving Machine

Overview Package size per unit product 260.00cm * 280.00cm * 1250.00cm Gross weight per unit product 2500.000kg Product

Basic Info

| Model NO. | APM-SM-1300B |

| Precision | High Precision |

| Certification | CE, ISO9001: 2000 |

| Warranty | 1 Year |

| Customized | Customized |

| Condition | New |

| After-sales Service | Yes |

| Weaving Width | 1300mm |

| Weight | 2500kg |

| Mesh Count | 0-600mesh |

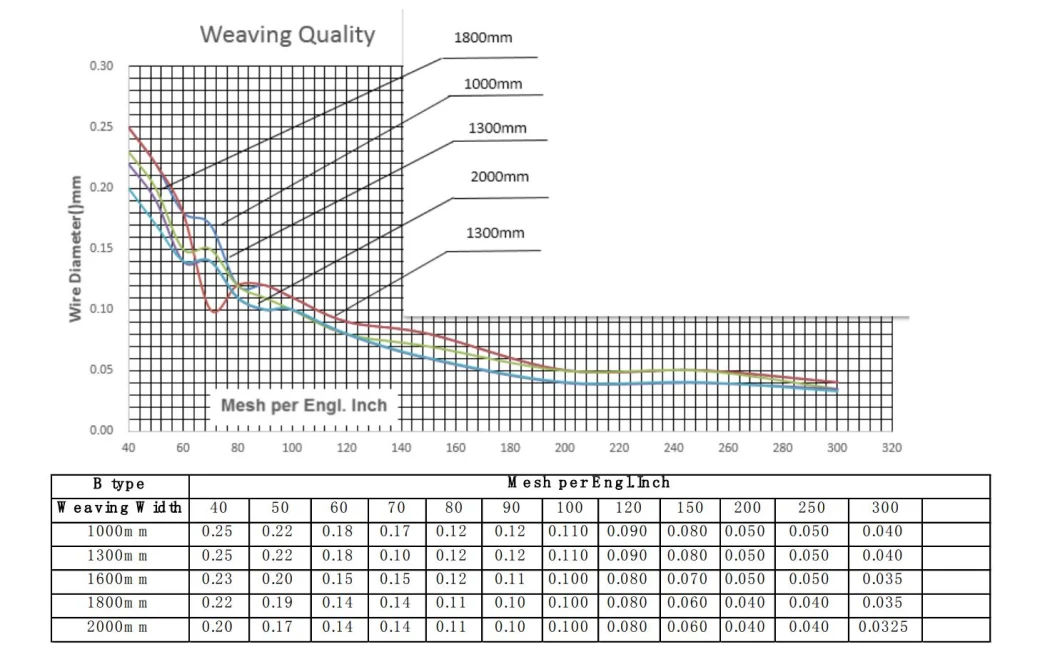

| Wire Diameter | 0.03-0.3mm |

| Wire Material | Ss,Al,Copper,Brass,Nickel,etc. |

| Weaving Type | Plain,Twilled,Dutch,Twilled Dutch |

| Shaft | 2,4 |

| Transport Package | Naked Cargo |

| Specification | 2600mm*2800mm*1250mm |

| Trademark | APM |

| Origin | Hebei, China |

| HS Code | 8446309000 |

| Production Capacity | 2000 Pieces/Year |

Packaging & Delivery

Package size per unit product 260.00cm * 280.00cm * 1250.00cm Gross weight per unit product 2500.000kgProduct Description

Product Description▪ All is full automatic ,such as warp wire feeding, shuttleless weft leading, rolling of mesh, braking and warning systems when the wire isbroken.

▪ Adaptability to various kinds of metal wire.

▪ Servo motor control.

▪ Automatic compensation of longitude wire and mesh rolling.

▪ Automatic stop and alarm for broken wire.

CNC machine Benefits:

CNC will adjust the mesh size automatic within the mesh range,

and keep the uniform opening size.

Length per roll could reach 500meter length.

It is better in filter industry wire mesh.

If the wire quality is better,the machine can work day and

24 hours working,night not need worker. you should do the perfect warping.Product Parameters

| Type | APM-SWJ-1300B Full PLC2 servo motor | APM-SWJ-1300B Full PLC 3servo |

| Mesh | PW: 40-600mesh DW to 2600mesh | PW: 0-250mesh |

| Wire Diameter(mm) | <0.30mm | <0.30mm |

| Weave Width | 1300mm | 1300mm |

| Speed | 60-120T/min with frequency | 60-120times /min with frequency |

| Rated voltage(v) | 420 3phases 2.2 kwa | 380V 3phases 2.2 KW |

| OutSize(m) | 2900*2400*1360mm | 2900*2400*1580mm |

| Weight(kg) | 3100 | 3500 |

| Rapier | Carbon Fiber Rapier | Servo Motor control Carbon Fiber rapier |

| Nylon Rapier | Servo Motor 2.3KW | |

| Cloth Take-up system | Servo+reducer | Servo + reducer |

| Warp Let-off system | Servo+reducer | Servo + reducer |

| Weave type | Plain, Twill, Dutch | Plain, Twill, Dutch |

| Heddle Frame | 4 | 4 |

| Beat time | 1 | 1 |

The weaving specification in plain

Full PLC

3 servo motor

Endless cloth take-up(3 rollers to take up the cloth without machine stop when cut the cloth off)APM-SWJ-1300B/1600B

Full PLC

2 servo motor(rapier driven by gear)

Endless cloth take-up(3 rollers to take up the cloth without machine stop when cut the cloth off)APM-SWJ-1300B/1600B

Full PLC

3 servo motor

Limited cloth take-up(single roller to take up cloth,must stop the machine when cut off the cloth)

Company Profile

Hebei Zonghang Machinery manufacture is new name for export and the old name is Jinjingwei Machinery manufacture which

began to operate in 1983 and divided from our machinery factory in 1995. We are only professional in weaving wire mesh

machine for over 20years old.

Our main machine range: Crimped wire mesh weaving machine, Shuttleless wire mesh weaving machine, knitting mesh machine,

Expanded metal mesh machine, Razor barbed wire machine, etc.

With the good service an high technology quality machine, We got proved and praise from our clients. From 2008 to till now. Our

machine are widely exported to India, Egypt, France. Iran, Indonesia. Malaysia. Jordan, Bahrain and Africa etc. 25countries till now.

After Sales Service

Sale service:

Maintenance period: one yearWe can send our technicist to the buyers' place to debug the machine and providing the training in 30 days after the machines arrive at the destination port.

The debugging fees: free

The training fees: First 7days is free , after that USD100/day for each technical

The numbers of technical persons: one technical person per machines at most.

The fees :round-trip tickets, accommodation etc, are all in buyers' account.

During the maintenance period:the parts damaged non-artificially will be provided free of charge. If buyers need the technicians,we will assign the technical

staff to your company. And the fees ,such as round-trip tickets,accommodation etc, are all in buyers' account.

After the maintenance period:If buyers need the machine parts, we will provide it as our cost. If buyers need the technicians, we will assign the technical

staff to your company. And the fees ,such as round-trip tickets,accommodation etc, are all in buyers' account.

Auxiliary machineMore products