- Stranding Machine

- Double Twist Machine

- Single Twist Cabling Machine

- Core Wire Extruder Machine

- Sheath Cable Extruder Machine

- Wire Drawing Machine

- Twist Buncher Machine

- Double Twist Stranding Machine

- Foaming Extruder Machine

- Armoring Machine

- Copper Tape Shielding Machine

- Steel Tape Armoring Machine

- Take Up Machine

- Pay Off Machine

- Motorized Pay Off Machine

- Passive Pay Off Machine

High Speed Fiber Cable / Copper Wire Sheath Extruder/ Cable Extrusion Machine

Basic Info

| Model NO. | LTM |

| After-sales Service | Provided |

| Driven Type | Electric |

| Condition | New |

| Certification | CCC, ISO, CE |

| Warranty | 12 Months |

| Screw | Double-Screw |

| Length to Diameter Ratio | 25:1 |

| Model No. | Longterm |

| Nitrogen Depth | 0.5~0.7mm |

| Center Height of Production Line | 1000mm |

| Axis Runout Accuracy | 0.05mm |

| Hardness | >940 |

| Wire Reel Size | 630~800mm |

| Production Line Structure Speed | 200m/Min |

| Pay-off Structure Speed | Max200m/Min |

| Extrusion Molding Machine | Sj65-25 |

| Steel Wire Reel Shaft Hole Size | 80mm |

| Optical Fiber Diameter | 0.254mm |

| Transport Package | Standard Seaworthy Package |

| Specification | Customized |

| Trademark | Longterm |

| Origin | Jiangsu, China |

| HS Code | 847720900 |

| Production Capacity | 400 Sets/Year |

Product Description

High Speed Fiber Cable / Copper Wire Sheath Extruder/ Cable Extrusion Machine

What is Fiber Optic Cable?Optical fiber cable (optical fiber cable) is manufactured to meet optical, mechanical or environmental performance specifications. It is a communication that uses one or more optical fibers placed in a sheath as a transmission medium and can be used individually or in groups Cable assembly. Optical cables are mainly composed of optical fibers (thin glass filaments such as hair), plastic protective sleeves and plastic sheaths. There are no metals such as gold, silver, copper and aluminum in the optical cables, and generally have no recycling value. An optical cable is a communication line in which a certain number of optical fibers compose a cable core in a certain way, and are covered with a sheath, and some are also covered with an outer sheath to realize the transmission of optical signals. That is: a cable formed by an optical fiber (optical transmission carrier) through a certain process. The basic structure of optical cable is generally composed of several parts such as cable core, reinforced steel wire, filler and sheath. In addition, there are waterproof layer, buffer layer, insulated metal wire and other components as required.

Raw material (PP,PE,PA,PET)--------Pay-off --------Caterpillar------ Extruder head------Water cooling------Drying--------Caterpillar ------winder/take -up machine

It is used to produce butterfly-shaped optical cables, and the sheath material is LSZH low-smoke halogen-free fuel resistance.Application:

Covered optical cables are mostly single-core and double-core structures, and can also be made into four-core structures. The cross-section is in the shape of a figure. The reinforcement is located at the center of the two circles. Metal or non-metal structures can be used. The optical fiber is located in the geometric center of the figure. Technical Parameters:| Geometric size of butterfly optical cable | 2mm~2.5mm×3mm~6.5mm |

| Production line structure speed | 200m/min |

| Production line speed | 150m/min (Related to material) |

| Pay-off reel size | Φ236×Φ25.4×108mm(25KM Reel)Φ265×Φ25.4×180mm(50KM Reel) |

| Fiber pay-off tension | 0.5N~5N(Adjustable) |

| Extrusion molding machine | SJ65-25 |

| Take-up tension | 5N~30N(Adjustable) |

| Take-up reel size | PN280/PN630 |

| Production line direction | To be determined |

| Production line color | To be determined |

| Center height of production line | 1000mm |

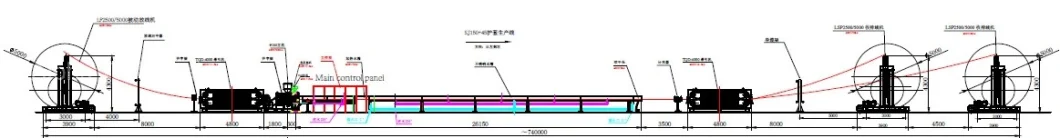

Composition of production line:

| PN600-PN800 active swing arm type steel wire active pay-off rack | 1set |

| Four-in-one automatic pay-off machine | 1set |

| 100kg drying and loading device | 1set |

| SJ65-25 Extruder molding machine Length-diameter ratio 25:1, LSZH screw | 1set |

| Stainless steel double-layer heat preservation and heating mobile sink | 4m |

| Stainless steel double-layer heat preservation and heating water tank 6KW | 1set |

| Stainless steel cold water tank | 12m |

| Water bath type Φ630 wheel tractor (and cold water tank) | 1set |

| Blow dryer | 1set |

| Refrigeration unit 3HP | 1set |

| Two-way diameter measuring instrument (Gongjiu) | 1set |

| 150m wire storage rack and tension controller | 1set |

| Meter counting, ink-jet printing anti-shake guide, crimping stop and retreat integrated device | 1set |

| Double reel take-up machine | 1set |

| Electric control system | 1set |

We are a collection of scientific research and development and production of wire and cable equipment and a variety of efficient energy-saving extrusion production line of key enterprises, so far, the main product including wire and cable Insulation and Sheathing production Line, TQD series Pneumatic Type belt puller LF series Portal Type Pay-off, LSP series Portal Type Take-up, Various Wire Accumulator, Capstan Haul-off, Pay-off & Take-up, Cooling Water Trough, and Optical Fiber Equipment, Communication Cable Equipment, Signal Cable Equipment.Our company has a technical administration team who engages wire and cable equipment industrial more than twenty years, as well as an experienced engineer and skilled workers, our honest business reputation and good sales achievement, win the trust from our domestic and overseas customers, the products are exported to United States, France, Spain, Portugal, New Zealand, Brazil, Mexico, Chile, South Africa, Zambia, Egypt, South Korea, Singapore, Indonesia, Thailand, Iran, etc.The company passed through the certification of "Quality Credibility Enterprise" Furthermore, in May 2010, HNanfang Electro technical" has been entitled as "China famous brand" by State Quality Supervision Bureau.We expand investment in the year 2010, enhance our competitiveness to satisfy customers needs. 12000 square meters new workshop will be operated, and more new processing equipments will be invested, and specialist management expert will join us in 2001. "Quality guarantees our excellent product,credit outstanding create well-know brand",we will continuously provide our best product and excellent after-sale service to every old and new customer, create real value to every user.

FAQ− Q: Are you the manufacturer or trading company?

A: We are the manufacturer. We have a group of highly qualified engineers and experts, who have been working in the field of OFC equipment for more than ten years.

− Q: What is your company's main production?

A: We specialized in optical fiber and optical cable machine researching and manufacturing. Our products include Optical fiber coloring and rewinding machine series, Optical fiber secondary coating line series, Optical cable stranding line, Optical fiber cable sheathing line series and other optical cable equipment.

− Q: What can we offer our customers?

A: Our professional production and technical personnel can train our customers' employees and ensure the smooth production of customers. And will provide our customers with after-sales service.

− Q: How long is the machine warranty?

A: Warranty period of one year (since the completion of mechanical debugging at the buyer's factory)

− Q: Why do I choose your company? A: We have more than 10 years of professional experience in the production of cable machinery, providing high-quality, high-security products.

We have an experienced team of skilled workers and engineers.

We can support overseas training engineers.

We can customize the design, to accept the customer's sample design.

We can provide customers with after-sales service.

Enable us to send you an accurate machine offer. pls kindly send us the following information:1. How many kgs/meters to extrusion per hour? 2. Reel/Flange Diameter, we need to quote correct take-up and pay off machine 3..Could you please send us your cable structure? 4. Extrusion material of cable sheath and Cable sheath thickness 5.Cable size 6.Cable pulling speed