Category

- Stranding Machine

- Double Twist Machine

- Single Twist Cabling Machine

- Core Wire Extruder Machine

- Sheath Cable Extruder Machine

- Wire Drawing Machine

- Twist Buncher Machine

- Double Twist Stranding Machine

- Foaming Extruder Machine

- Armoring Machine

- Copper Tape Shielding Machine

- Steel Tape Armoring Machine

- Take Up Machine

- Pay Off Machine

- Motorized Pay Off Machine

- Passive Pay Off Machine

High Speed Double Twisting Stranding Machine

High Speed Copper Wire Cable Double Stranding Twisting Machine It is applicable for stranding PVC or other plastic insul

Basic Info

| Model NO. | WLT1250 |

| Driven Type | Electric |

| Condition | New |

| Certification | RoHS, ISO, CE |

| Warranty | 12 Months |

| Automatic Grade | Automatic |

| Mould Life | 300,000-1,000,000 Shots |

| Type | Double Twist |

| Model | 1250mm 1600mm |

| Motor | Siemens AC Motor |

| Driver | Yasikawa or Siemens Inverter |

| Bearing | NSK |

| Driving Belt | Ep |

| Low Voltage Electric Part | Siemens or Schnerder |

| PLC | Siemens |

| OEM Service | Positive |

| Transport Package | Sea Worthy Package |

| Specification | SGS |

| Trademark | WELLION |

| Origin | China |

| HS Code | 8477900000 |

| Production Capacity | 50 Units/Year |

Product Description

High Speed Copper Wire Cable Double Stranding Twisting Machine

It is applicable for stranding PVC or other plastic insulated wires with features of high speed and stable twisting pitch.- General Specification:

| Application | 5 PVC | 7 CU/AL | 19CU/AL |

| Inlet wire diameter(mm) | 1.2---3.2 | ||

| Max. cross section(mm2) | 50 | 70 | |

| Finished diameter(mm) | 22 | 9.5 | 11 |

| Laying pitch(mm) | 50---500 | 40---300 | 50---500 |

| cradle fly rotation speed | 900 RPM / Max. (1800 Twist) | ||

| Bobbin size | 1250mm X 950mm X 80mm(bore) | ||

| Bobbin lifting | Pintle type; with electro motion platform | ||

| Power supply | 380V 50HZ | ||

| Air supply | 6 kg-cm2 | ||

| Brake system | Pneumatic Disk brake | ||

- Main Components:

| No. | Q'ty | Unit | Name | Type | Maker |

| 01-1 | 1 | Set | Pay off | 7 heads flyer pay off | WELLION |

| 02-0 | 1250mm Double twisting machine | WELLION | |||

| 02-1 | 1 | Set | base of the inlet | WELLION | |

| 02-2 | 1 | Set | transmission system | WELLION | |

| 02-3 | 1 | Set | power | WELLION | |

| 02-4 | 1 | Set | rotation body | WELLION | |

| 02-5 | 1 | Set | cradle fly | WELLION | |

| 02-6 | 1 | Set | cradle body | WELLION | |

| 02-7 | 1 | Set | die for wire through | WELLION | |

| 02-8 | 1 | Set | traversing unit | WELLION | |

| 02-9 | 1 | Set | take off unit | WELLION | |

| 02-10 | 1 | Set | spooler tension unit | WELLION | |

| 02-11 | 1 | Set | bobbin load /unload | WELLION | |

| 02-11 | 1 | Set | stranding lay length control unit | WELLION | |

| 02-12 | 1 | Set | electric control unit | WELLION | |

| 02-13 | 1 | Set | safety cover | WELLION | |

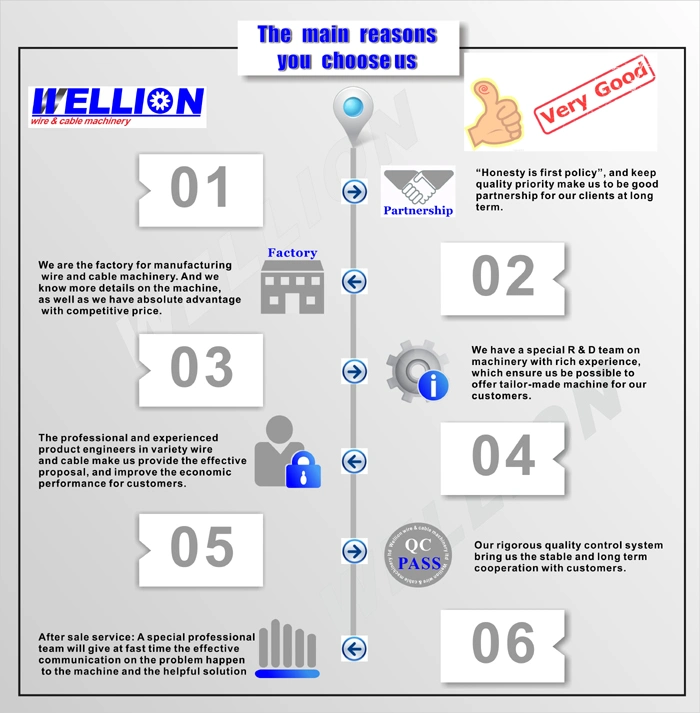

Our Services: It is able for us to offer customer the pre-sale services of providing customized design the production line based on special requirement of products, as well as configuring the production plant drawing of equipment arrangement if necessary, and accessing the factory environment. Also we are able to provide service of training the customer's technicians in operation the machine and technical support in making wire cable.About After-sale services, we have obligation to offer installation and commissioning service in customer's factory. Also the regular maintenance and product tracking service will be done in machine lifetime. Any problem can be feedback to our company pointed service man at any time, and the solution is going to be given with high quality and efficiently.Why Choose US?

Wellion company factory: