Category

- Stranding Machine

- Double Twist Machine

- Single Twist Cabling Machine

- Core Wire Extruder Machine

- Sheath Cable Extruder Machine

- Wire Drawing Machine

- Twist Buncher Machine

- Double Twist Stranding Machine

- Foaming Extruder Machine

- Armoring Machine

- Copper Tape Shielding Machine

- Steel Tape Armoring Machine

- Take Up Machine

- Pay Off Machine

- Motorized Pay Off Machine

- Passive Pay Off Machine

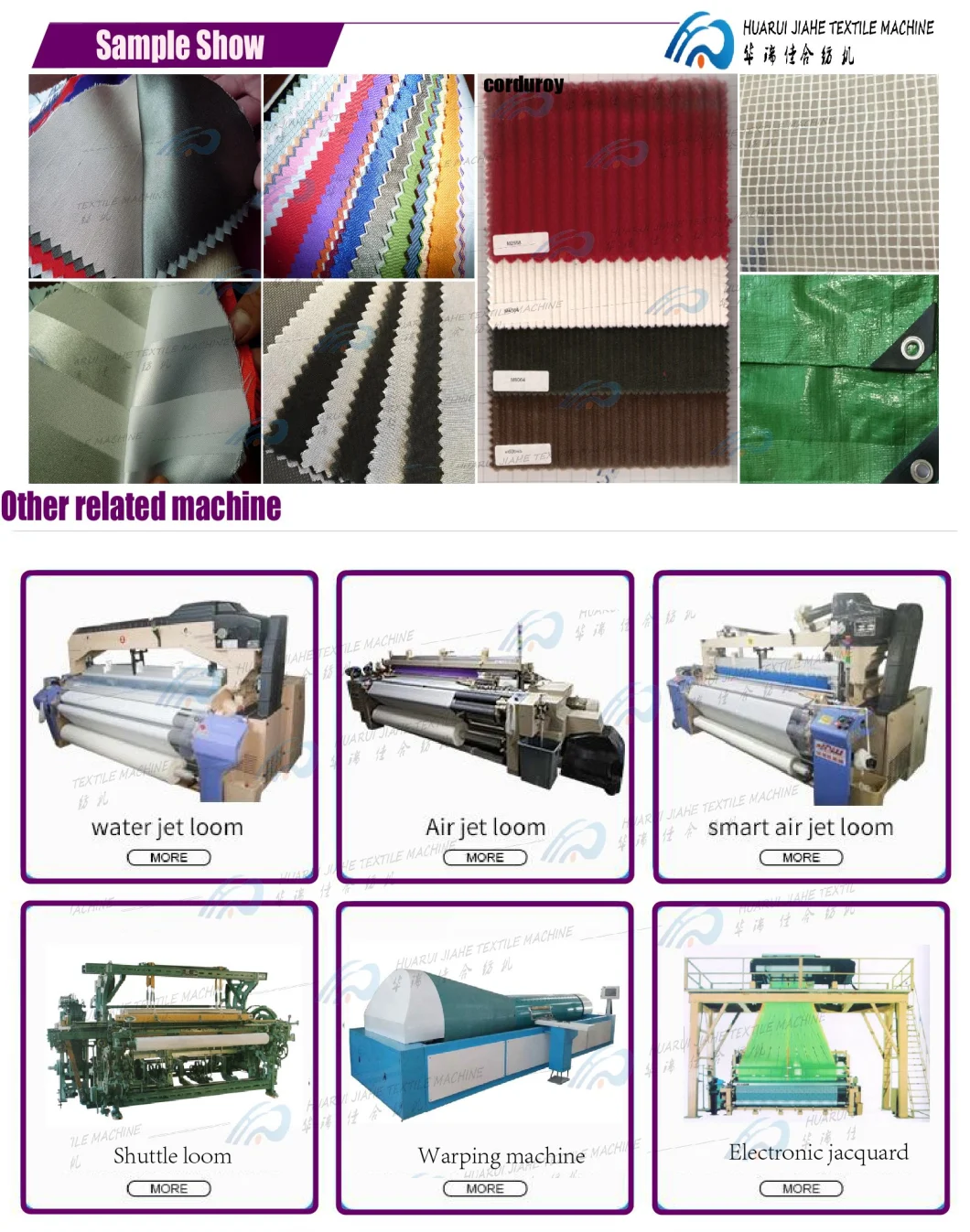

Water Jet Machines Electronic Take up and Let off Mechanical Feeder Water Jet Loom 280cm Two Nozzle Dobby Shedding Water Jet Loom Waterjet Machines

Application: .The frame of the whole machine is enlarged ,which expands the area of support of the beam. .The machine ha

Basic Info

| Model NO. | HR |

| Type | Water Jet Loom |

| Voltage | 380V |

| Computerized | Computerized |

| Precision | High Precision |

| Certification | CE, ISO9001: 2000 |

| Warranty | 1 Year |

| Customized | Customized |

| Condition | New |

| Item | Fruit Net Making Machine Water Jet Loom |

| Machine Painting Color | Be Made According to Your Need |

| Price | Lowest Reasonable Offers in The Market |

| Delivery Time | 5 Days |

| After-Sales Service Provided | Engineers Available to Service Machinery Overseas |

| Working Experience | 32 Years′ Experience |

| Total Power | 1.5kw~5.4kw |

| Capacity | 600~1200rpm/Min(Actual Speed Depends on The Specif |

| Let-off | Mechanical Let-off/ Electronic Let-off |

| Take-up | Mechanical Take-up/ Electronic Take-up |

| Drying | by Suction Blower Device |

| Nozzle | Single Nozzle/ Double Nozzle/ Three Nozzle/ Four N |

| Heald Frame | Standard 6 Pieces Frame |

| Shedding | Plain/ Cam/ Dobby |

| Cutter | Mechanical Cutter |

| Transport Package | Standard Package, Be Made According Cutomer Need |

| Specification | 130, 150, 170, 190, 210, 230, 260, 280, 320, 340, |

| Trademark | HUARUI |

| Origin | Qingdao City |

| HS Code | 84451190 |

| Production Capacity | 100 Sets / Month |

Product Description

Application:.The frame of the whole machine is enlarged ,which expands the area of support of the beam.

.The machine has been innovated and improved in the aspects of transmission, cam and dobby shedding and let-off and take-up system .

.it is quite suitable for the high speed and stable weaving of heavy and high-density fabric.

Technical data| Reed Width(cm) | 130, 150, 170, 190, 210, 230, 260, 280, 320, 340, 360 |

| Nozzle | Single nozzle/ Double nozzle/ Three nozzle/ Four nozzle |

| Installed Power | 1.5kw~5.4kw |

| Speed | 600~1200rpm/min(Actual speed depends on the specifications of fabric) |

| Heald Frame | standard 6 pieces frame |

| Shedding | Plain/ Cam/ Dobby |

| Let-off | Mechanical Let-off/ Electronic Let-off |

| Take-up | Mechanical Take-up/ Electronic Take-up |

| Electronica Power Source | 380v/415v |

| Drying | By Suction Blower Device |

| Cutter | Mechanical Cutter |

| Leno Device | Planetary Gear Type |

Standard Configuration:

Name of the parts | Configuration |

| Wallboard | from our company ,heavier |

| Bearing | NSK, Made in Japan,or FAG Made in German |

| Plunger | AWA, Made in Korea,or Taiwan |

| Spring, Non-returning valve | MDH, Made in Korea, or Taiwan |

| Oil Seal | TTO, Made in Taiwan |

| Bush | Dubang, Made in USA |

| Electronic Feeder | SANHE/ZHONGSEN, Made in China |

| CVT/Zero Max | Shimpo, Made in Japan |

| Pump | JILONG, Made in China |

| Nozzle | MDH, Made in Korea(Ceramic) |

| Belt | Mistubishi, Made in Japan |

| Reed Holder | Stainless steel 304 |

3 Main Feature:

1.high speed , heavy duty and great stability2. it is quite suitable for weaving of heavy and high density fabric3.running smoothly , high efficiency and speed up to 1200rpm

Detail machine pictures, all photoes are for 100% real shooting ! For more pictures, video and details, please email me!