Category

- Stranding Machine

- Double Twist Machine

- Single Twist Cabling Machine

- Core Wire Extruder Machine

- Sheath Cable Extruder Machine

- Wire Drawing Machine

- Twist Buncher Machine

- Double Twist Stranding Machine

- Foaming Extruder Machine

- Armoring Machine

- Copper Tape Shielding Machine

- Steel Tape Armoring Machine

- Take Up Machine

- Pay Off Machine

- Motorized Pay Off Machine

- Passive Pay Off Machine

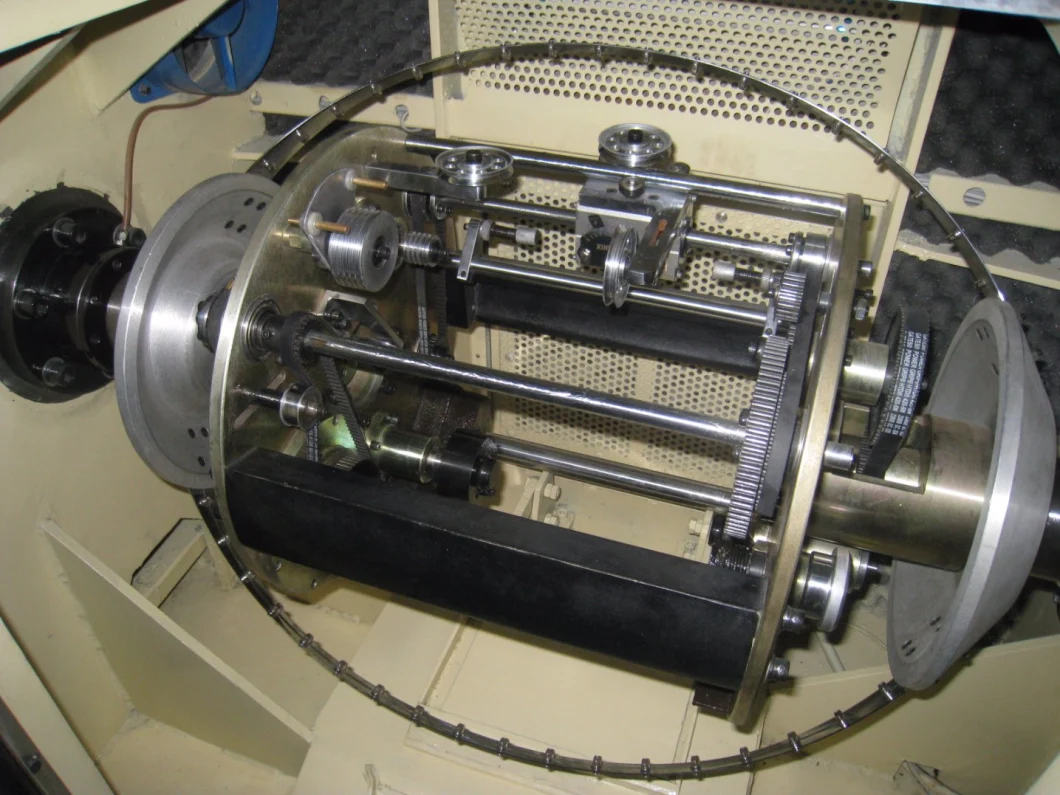

0.05-0.64mm Electrical Copper Cable Wire Making Double Twisting Bunchers Bunching Stranding Winding Machine

Main performance parameters of FC-300B high speed bunching machine (replace of the capstan wheel to change the lay lengt

Basic Info

| Model NO. | FC-300B/400B/500B/650B/800B/1000B/1250B |

| Appliable Wire Diameter | 0.05-0.28mm |

| Twisting Usage | Twisting Wire Medical Equipment, Cellphone |

| Stranding Section Area | 0.0137-0.45mm2 |

| Pitch | 1.6-21.6(24zones) |

| Direction of Lay | Optional for Right or Left |

| Max Rotating Speed | 3500rpm(7000twist) |

| Main Motor Power | 3.7kw |

| Inverter Power | 3.7kw |

| Tension Control Method | Touch Screen+PLC+Magnetic Powder Clutch |

| Magnetic Powder Clutch | 0.6kgf |

| Transport Package | Simply Packed |

| Specification | ISO9001 |

| Trademark | FC |

| Origin | China |

| HS Code | 8479811000 |

| Production Capacity | 60set/Month |

Product Description

Main performance parameters of FC-300B high speed bunching machine (replace of the capstan wheel to change the lay length).- Usage:It is applied to the stranding of bare twisted wire, tinned, copper covered aluminum, lacquer wire and alloy wire. 1+6 may bunching instead of twisting.

| Equipment model | FC-250B | FC-300B | FC-400B | FC-450B |

| Twisting usage | Apply for the bunching of aerospace,medical instrument,cellphone,notebook And ultra fine conductor(above seven pcs of alloy wires,tinned wires,silver jacketed wires and enamelled wires) | |||

| Single wire dia(mm) | 0.03-0.18 | 0.04-0.28 | 0.05-0.32 | 0.05-0.32 |

| Stranding section area(mm2) | 0.0049-0.3 | 0.0088-0.45 | 0.0137-1.0 | 0.0137-1.0 |

| Pitch(mm) | 0.8-10.8 | 1.6-21.6 | 3.1-33.3 | 3.1-33.3 |

| Direction of lay:optional for right or left | ||||

| Take up bobbin | 200-250 | 250-300 | 300-400 | 300-450 |

| Max rotating speed | 4000rpm(8000TPM) | 3500rpm(7000TPM) | 3000(6000TPM) | |

| Main motor power:3.7KW | ||||

| Inverter power:3.7KW | ||||

| Tension control:PLC+touchscreen +magnetic powder clutch,ensure the constant tension from empty to full bobbin | ||||

| Magnetic powder clutch | 0.3kgf | 0.6kgf | ||

| Protection:automatically brake/stop 1)wire inside and outside is broken 2)the preset length is arrived | ||||

| Brake mode | Electromagnetic brake | |||

| Traversing method:rolling wire with ring drive units,winding pitch and width are adjustable | ||||