Category

- Stranding Machine

- Double Twist Machine

- Single Twist Cabling Machine

- Core Wire Extruder Machine

- Sheath Cable Extruder Machine

- Wire Drawing Machine

- Twist Buncher Machine

- Double Twist Stranding Machine

- Foaming Extruder Machine

- Armoring Machine

- Copper Tape Shielding Machine

- Steel Tape Armoring Machine

- Take Up Machine

- Pay Off Machine

- Motorized Pay Off Machine

- Passive Pay Off Machine

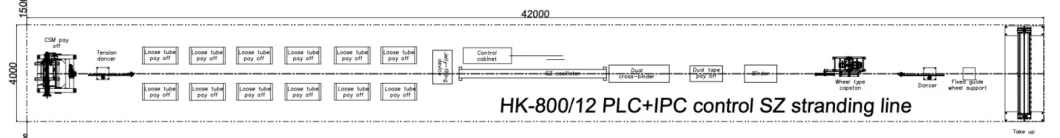

Sz Stranding Machine for ADSS Optic Cable Production Line

Overview Package size per unit product 28.00cm * 2.00cm * 2.00cm Gross weight per unit product 9600.000kg Sz Stranding M

Basic Info

| Model NO. | HK-800/12 |

| Allowed Lateral Pressure | >1000(N/100mm) |

| Allowed Tensile Strength | >10000N |

| Core | 12 |

| Brand | Siemens |

| Sheath Material | PVC |

| Usage | Optic Cable Stranding |

| Loose Tube Diameter | 1.6-4.5mm |

| Extrusion Material | PBT |

| Structure Speed | 320m/Min |

| Service | Technical Support, Training |

| Motor | Siemens |

| System | PLC+Ipc Control |

| Power | Three Phase Five Line 380V 50Hz |

| Loose Tube | Pn630-800mm |

| No of Loose Tube | 12 Pieces |

| Transport Package | Plastic Film+Wooden Package |

| Specification | length: 38m |

| Trademark | HK |

| Origin | Guangdong Dongguang |

| HS Code | 8477900000 |

| Production Capacity | 3sets/Month |

Packaging & Delivery

Package size per unit product 28.00cm * 2.00cm * 2.00cm Gross weight per unit product 9600.000kgProduct Description

Sz Stranding Machine for ADSS Optic Cable Production LineMachine's Application

Our Sz Stranding Machine for ADSS Optic Cable Production Line is a state-of-the-art solution designed for the efficient and high-quality manufacturing of fiber optic cables. With advanced technology and precision engineering, our production line can handle a wide range of cable sizes and specifications, ensuring the perfect fit for your specific needs. Our line includes a range of key components, such as fiber coloring machines, extruders, and high-speed optical fiber stranding machines, all designed to deliver exceptional performance and reliability.

Main Overview

| Reinforcement core pay-off reel specification | PN800-PN1250MM |

| Tension wheel diameter | Ø800mm(double wheels) |

| Pay-off reels no of optical-fiber bundle tube | 12reels(according to clients' requirement) |

| Max laying-up outer diameter | Ø32mm |

| Production speed | Max.85m/min |

| Laying-up pitch(single screw ) | (80-1500mm)±5-10mm |

| SZ stranding angle | ±(4-24)π |

| The max revolution speed of cotton wrapping head | 3000rpm |

| The max revolution speed of SZ stranding heads | 850rpm |

| Cotton wrapping pitch | 20mm-50mm |

| Reinforcement core pay-off tension | 50N-300N |

| Take-up tension | 50-150N |

Main Brand We Are Using

Motor: Siemens (China) MotorTransducer: American Emerson transducerTemperature controller: Omron Brand PID Smart typeMan-Machine interface:10.2-inch colorPLC and Control Module: SiemensScrew and Barrel: Produced by jinghu Company.Bearing: Japan NSK or other same quality brandsLow voltage electrical parts: Adopts SIEMENS, OMRON, SCHNEIDER brands, etc.Machine's layout

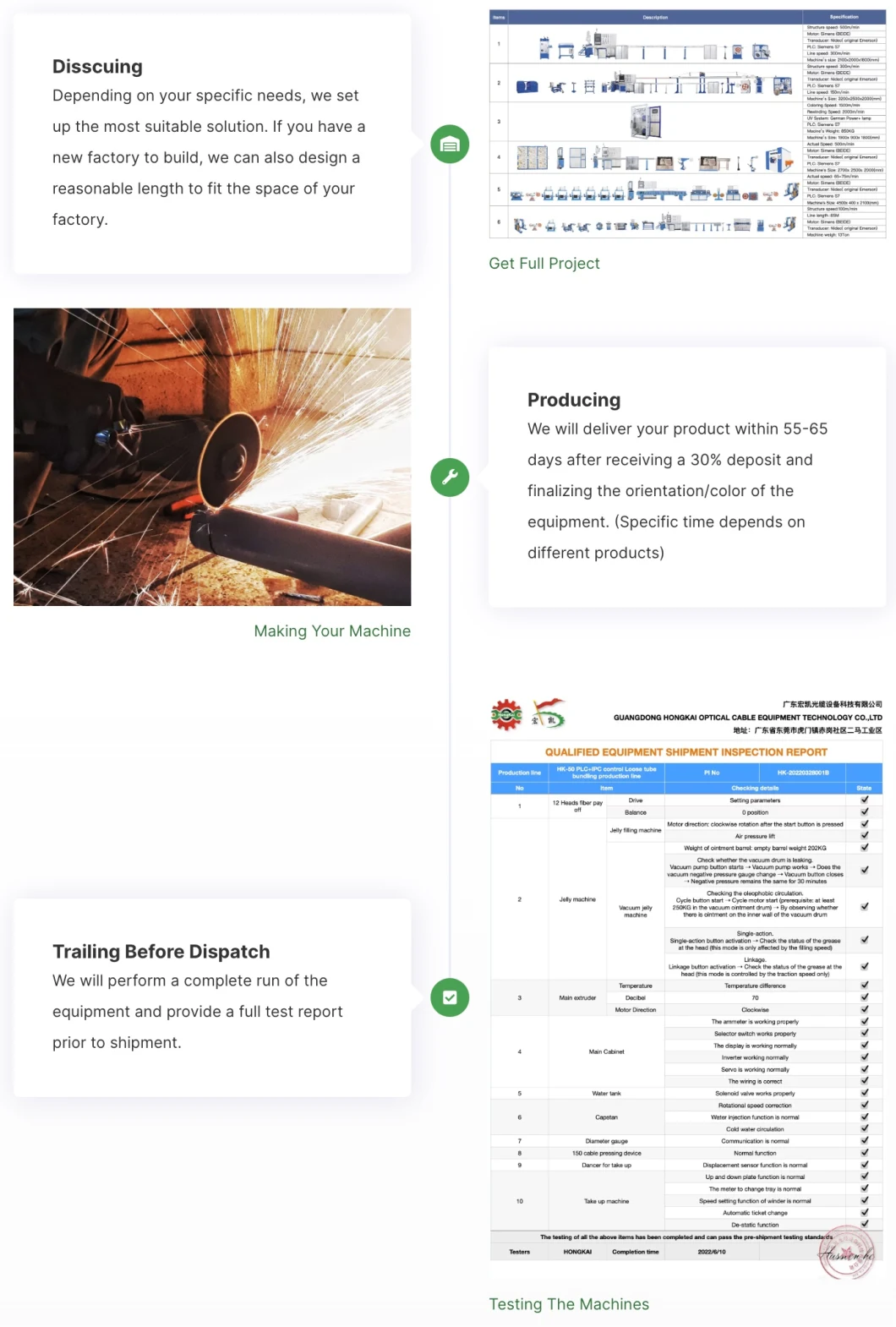

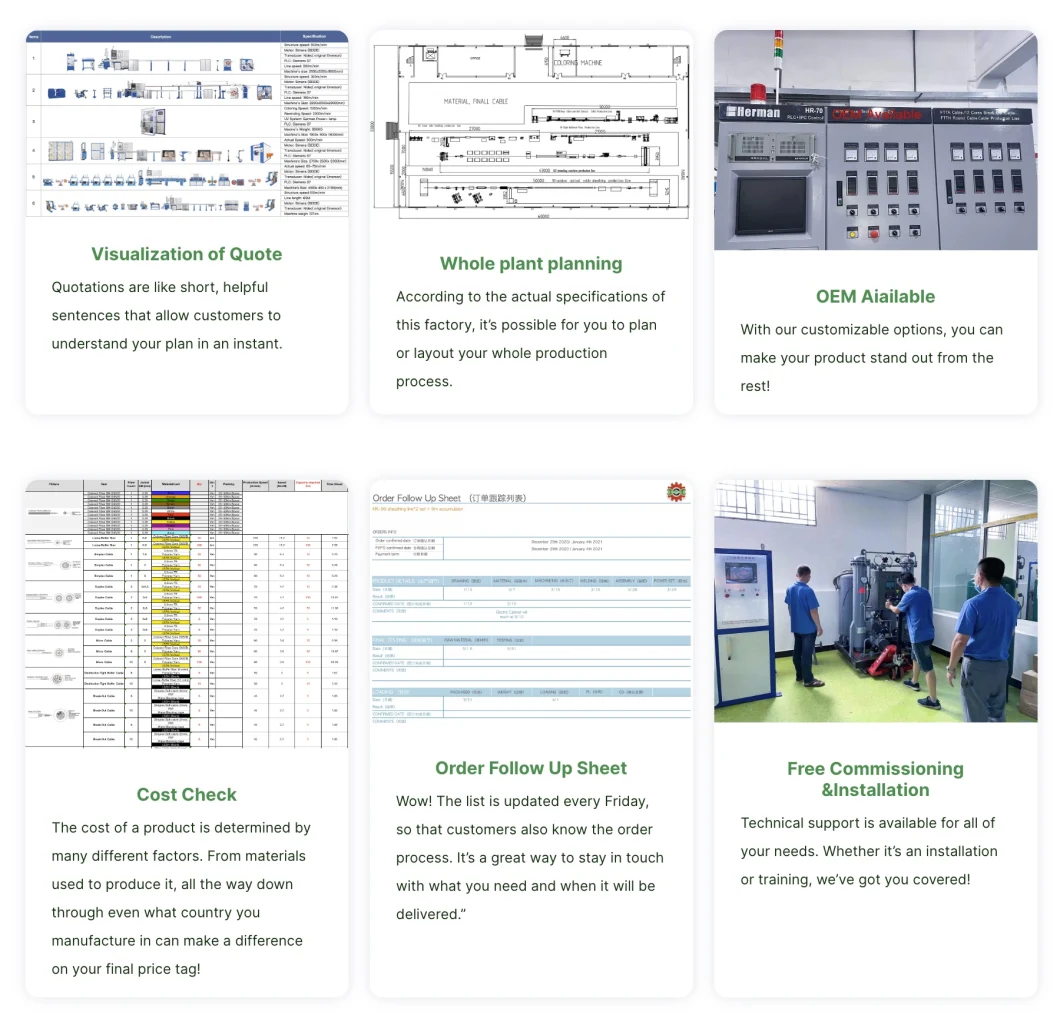

Steps Work With Us

Step 1: Discussing- Depending on your specific needs, we set up the most suitable solution. If you have a new factory to build, we can also design a reasonable length to fit the space of your factory.Step 2: Producing- We will produce the machine according to your exact requirement. Our engineers have many years of experience and work diligently to ensure that the quality of each machine is top-notch.Step 3: Testing- After production, we conduct a comprehensive test on every single component in the machine to ensure it meets your expectations.

Packing&Delivery

All the components and parts are packed separately, then placed in wooden cases or frames to prevent damage during transportation. We provide various delivery methods according to specific requirements.

Why Choice HONGKAI

FAQ

1. What industries do your equipment solutions cater to?Answer: Our equipment solutions cater to a diverse range of industries, including telecommunications, power transmission, automotive, and more.2. What customization options do you offer for your equipment?Answer: We offer a range of customization options for our equipment, including the ability to tailor equipment specifications to meet specific industry needs, integrate additional features and components, and provide specialized training and support.3. How do you ensure the quality and reliability of your equipment?Answer: We maintain strict quality control measures throughout the manufacturing process to ensure that our equipment meets the highest standards of performance and reliability. Our equipment is also extensively tested and inspected before shipping to ensure that it is in optimal condition upon arrival.4. What technical support and after-sales services do you provide?Answer: We provide comprehensive technical support and after-sales services, including on-site installation and training, ongoing maintenance and repairs, and assistance with troubleshooting and optimizing equipment performance.5. What is the lead time for delivery of your equipment?Answer: The lead time for delivery of our equipment varies depending on the specific product and order quantity. We work closely with customers to provide accurate delivery estimates and ensure the timely delivery of their equipment.6. Can you provide references or case studies of successful equipment installations in thepast?Answer: Yes, we can provide references and case studies of successful equipment installations in the past. Our team has extensive experience working with a wide range of customers and industries, and we are proud of the track record of success we have achieved over the years.