- Stranding Machine

- Double Twist Machine

- Single Twist Cabling Machine

- Core Wire Extruder Machine

- Sheath Cable Extruder Machine

- Wire Drawing Machine

- Twist Buncher Machine

- Double Twist Stranding Machine

- Foaming Extruder Machine

- Armoring Machine

- Copper Tape Shielding Machine

- Steel Tape Armoring Machine

- Take Up Machine

- Pay Off Machine

- Motorized Pay Off Machine

- Passive Pay Off Machine

Swan Ls3ty (J3) Special Cold-Welding Machine for Aluminum Alloy Flat Belt of Chain Armoring Machine

Basic Info

| Model NO. | LS3TY(J3) |

| Control Mode | Manual |

| Warranty | 1 Year |

| Function | Cold Weliding |

| Dimension | 550X550X920mm |

| Material | Cast Stainless Steel |

| Range of Wire | Width:0.25-21.00mm,Thickness0.25mm-4.00mm |

| Weight | 130kg |

| Marketing Type | New Product 2022 |

| Work Pressure | 6.5MPa |

| Power of Moter | 0.75kw |

| Type of Wire | Aluminum Alloy Flat Belt |

| Transport Package | Shipping in Carton |

| Specification | Customized Size |

| Trademark | Swan INT′L |

| Origin | China Shanghai |

Product Description

LS3TY(J3) Cold Welding Machine for Aluminum Alloy Flat Belt

Product Description

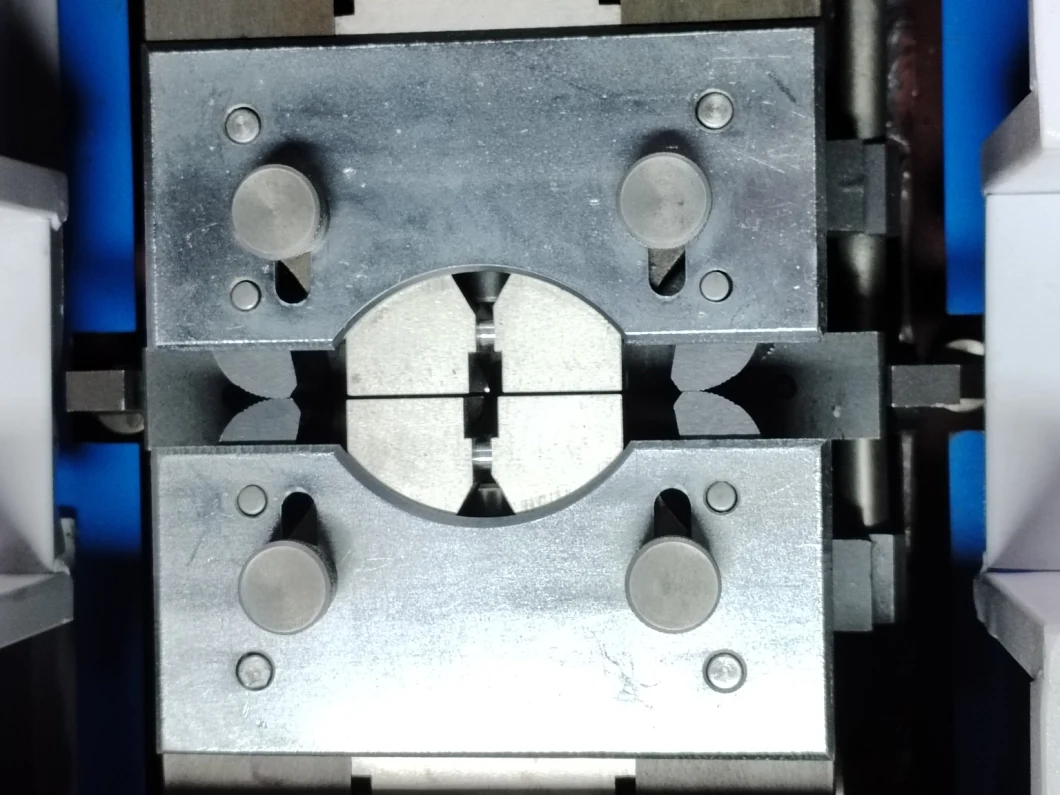

LS3TY cold welding machine is one of our special products, the frame is made of 45# steel, precision casting, the inner groove and plane of the upper body are finely ground by grinding machine, its opening mechanism is fully enclosed, which can prevent the copper chips from jamming the machine and causing bad wiring, so the design of the whole machine is very reasonable and ensures high precision. It is especially suitable for wiring in enameled wire workshop and finished product workshop. The machine is mainly used for export or domestic large enterprises.

Detailed Photos

Application

For Aluminum Alloy Flat Belt (Width:0.25-21.00mm,Thickness0.25mm-4.00mm)

Our Advantages

Our company has a complete set of advanced processing equipment and testing means. As our production is in streamline form, all produced sizes are up to the standard of our company. The key holes are bored by jig borer, thus avoiding the accumulated errors processed with several drillers. As a result , the tolerance and matching are excellent, parts can be interchangeable, thus guaranteeing the products to be high quality and good performance.In order to guarantee long life of our products, all castings used in our cold welders are made of high class nodular cast iron. Cast steel is 45# and is made of high quality precision casting, The V-shaped blocks and cams are american brand D2 steel. The steel is heattreated by a professional foreign enterprise strictly according to technical requirement of our company. Before putting it into use, the american steel is inspected by our inspection department, to guarantee its abrasion resistance and its undeformed ability.Relying on the used experience gained by our several thousands customers, We calculate out an ideal diameter size for arm shaft and handle shaft. We use high quality spring steel and treat it with tempering, to improve its solidity, and to avoid suchlike frequent encountered problems as breaking or curving in time of using these two shafts.

Packaging & Shipping

Reference to J3's packaging method

Company Profile

Similar Products Recommended

| Model | J0 | J1 | J2 | J3 | J5(with 5.5KW) |

| Wire range for Cu(mm) | 0.045-0.15 | 0.10-0.50 | 0.30-1.20 | 1.00-3.25 | 4.00-8.00 |

| wire range for Al(mm) | 0.07-0.15 | 0.10-0.50 | 0.30-1.40 | 1.00-5.00 | 4.00-15.00 |

| Size(mm) | 150*40*155 | 160*50*160 | 220*160*230 | 280*180*300 | 1190*570*1100 |

| Weight(kg) | 0.5 | 0.65 | 11 | 33 | 650 |

For cold welding machine , pls inform :

1, It is for copper or aluminum ; 2, What is the wire size range ( for cold welding machine selection ) ; 3: What is the specific wire size to be weldered ( For welding moulds selection ) .

About cold welder(cold welding machine)

The cold welder is a tool to joint nonferrous wires with the method of cold butt weld,There is no need to use electricity,heat,flux and electrode,thus saving such troublesome preteating works of metal wire as cutting and cleaning the wire.It only needs to thread two wire ends into a welding die,to match a suitable die depending upon the size of the wire,and then to press a handle of the welding machine several times,and the two wire ends get jointed.The result of such a welding is the same as the wire before welding,its tensile strength at the joint of the welded wire is good(equal to or even bigger than mother wire)and is not broken at th joint.lts resistivity is not bigger than that of original wire ,therefore such welding is not to be compared with other welding method.The merit of cold welding means simplicity in operation,with no need of extraordinary skill.With the method it is possible to ensure the reliability of welding,it is the most reliable and the most economic method to joint nonferrous wires and their allbys.