- Stranding Machine

- Double Twist Machine

- Single Twist Cabling Machine

- Core Wire Extruder Machine

- Sheath Cable Extruder Machine

- Wire Drawing Machine

- Twist Buncher Machine

- Double Twist Stranding Machine

- Foaming Extruder Machine

- Armoring Machine

- Copper Tape Shielding Machine

- Steel Tape Armoring Machine

- Take Up Machine

- Pay Off Machine

- Motorized Pay Off Machine

- Passive Pay Off Machine

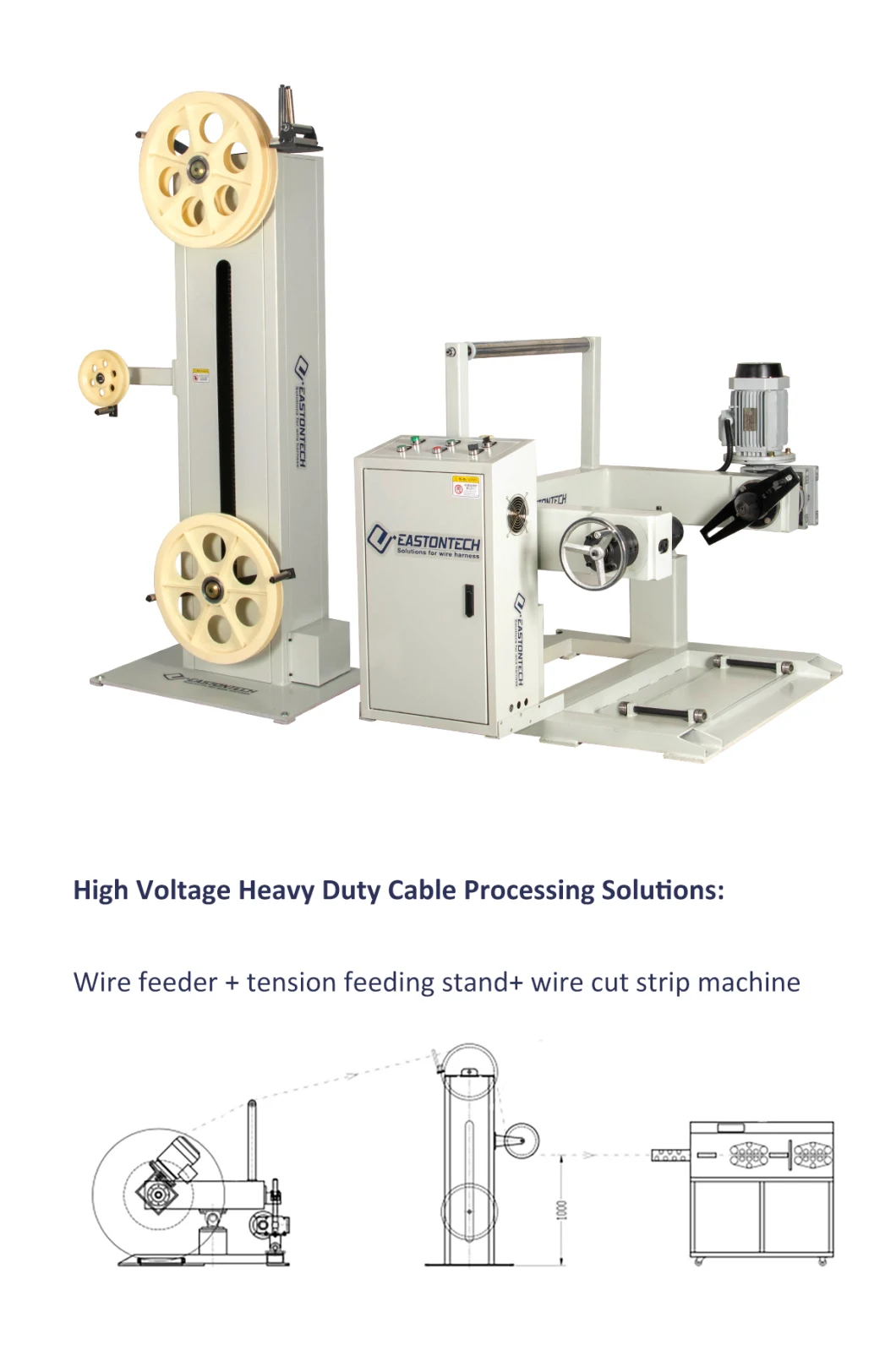

Eastontech Ew-1435 Big Weight Cable 1000kgs Automatic Spool Wire Pay off Machine Cable Wire Feeding Machine

Basic Info

| Model NO. | EW-1435 |

| Wire Tray Width | 250-500mm |

| Max. Capacity | 1000kgs |

| Power Supply | AC110/220 50/60Hz |

| Max. Feeding Speed | 250m/Min |

| Feeding Motor Power | 2.2kw |

| Machine Size | 167*162*132cm |

| Tension Stand Size | 207*80*62cm |

| Machine Weight | 550kgs |

| Transport Package | Wooden Box |

| Trademark | EASTONTECH |

| HS Code | 8428399000 |

Product Description

•It features a quick lock cam mechanism and motorized reel lifting system fro easy cable loading and fast changeover

•The feeding process allows rapid acceleration of the spool while maintaining low forces on the material being fed

•The integrated cable accumulator controls the speed of the dereeling drive

•The cable is led under constant tension to the cross cutting machine for trouble-free feeding

Model | EW-1435 | EW-1440 | EW-1445 |

Wire diameter | 3-20mm | 3-20mm | 3-20mm |

Wire tray size | OD 400-630, width 250-500 | OD 500-800, width 300-600 | OD 600-1000, width 450-750 |

Loading weight | 1000kgs | 1000kgs | 1000kgs |

Max. feeding speed | 250m/min | 250m/min | 250m/min |

Feeding motor power | 2.2KW | 4KW | 4KW |

N.W. | 550kgs | 550kgs | 600kgs |

Power supply | 220V/110V/50HZ/60HZ | ||

Application | Mainly suitable for the large square cables such as new energy wire , charging pile cables, power cables, photovoltaic wire, BV cable, etc. | ||

Feeding mode | Shaftless power pay-off, frequency converter automatically controls pay-off speed, automatic wire feed, automatic shutdown | ||

Question 1: What machines does the EASTONTECH mainly produce?Answer 1: We mainly produce machines for wire harness processing.Question 2: What are the main functions of your wire harness processing machine?Answer2: Our machine can complete cutting, stripping, crimping, tinning, soldering, binding&tying, etc.Question 3: What's the packaging and shipping?Answer3: Package: Standard export carton & wooden case.Shipping:By express: DHL, UPS, FedExWe will search for the most economical and reliable shipping company to transport the goods safely.By air: when your order is more than 100kg which will be more economical than expressBy sea: when your order is a large quantity, we can help you to deliver the goods by seaPort: Shanghai / Ningbo/ ShenzhenQuestion 4: How about after-service?Answer4: EASTONTECH parts are free to change if worn out within 1 year, provided the delivery fee is paid. Technical support is available during your daily maintenance.We promise to offer life-long maintenance for the products we sold.

HOT TAGS: Wire Cutting and Stripping Machine I Wire Stripping and Crimping Machine I Wire Stripping and Tinning Machine IWire Sealing and Crimping Machine I Wire Stripping Machine I Terminal Crimping Machine I Tape Cutting Machine I Terminal Crimping Applicator ITerminal Crimp Force Monitor I Terminal Pull Force Tester | Cable Stripping Machine I Ribbon Cable Crimping Machine I Wire Winding and Binding Machine I Heat Shrinkage Machine I Copper Belt Press Machine I Labeling Machine I Wire Harness Tester I Nylon Tying Machine I Tape Dispenser I Wire Feeding and Deposit/Coiling Machine I Tape Bundling Machine I Power Cord Production Machine